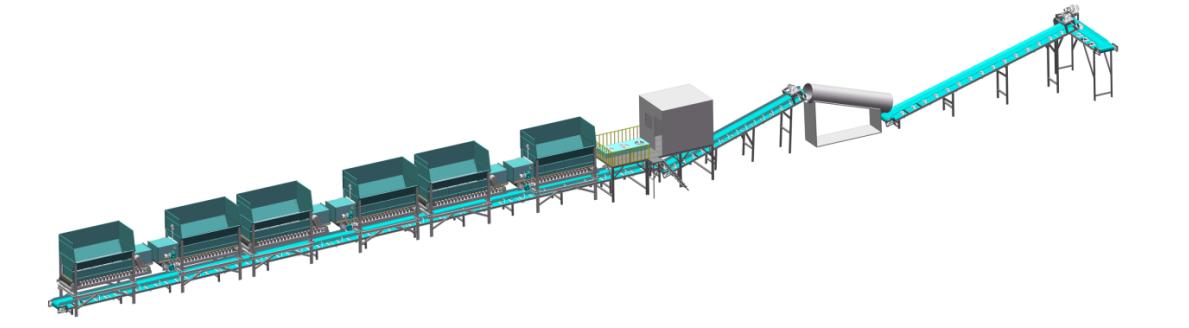

Factory Promotional Automatic Batching & Mixing & Conveying Systems yeExtruder Line

Rinogona kuva basa redu kugutsa zvaunoda uye kubudirira kukushandira iwe.Mufaro wenyu ndiwo mubairo wedu wakanakisisa.Isu tanga takatarisira kuenda kune kuwedzera kwakabatana kweFactory Promotional Automatic Batching & Mixing & Conveying Systems yeExtruder Line, Isu tinovimba nemoyo wese pakuchinjana nekushandira pamwe newe.Titendere kuti tiende mberi takabatana maoko uye tiwane win-win situation.

Rinogona kuva basa redu kugutsa zvaunoda uye kubudirira kukushandira iwe.Mufaro wenyu ndiwo mubairo wedu wakanakisisa.Isu tanga tichitarisira kuenda kune kuwedzera kwekubatana kweChina Extruder uye Kusanganisa Machine, Zvivakwa zvakasimba ndiko kudiwa kweimwe sangano.Isu takatsigirwa nenzvimbo yakasimba yezvivakwa inoita kuti tikwanise kugadzira, kuchengeta, kutarisa kwemhando uye kutumira zvinhu zvedu pasi rese.Kuti tichengetedze kufamba kwakanaka, takaisa zvivakwa zvedu mumadhipatimendi akati wandei.Madhipatimendi ese aya anoshanda nemidziyo yazvino, michina yemazuva ano nemidziyo.Nekuda kweizvozvo, isu tinokwanisa kuzadzisa kugadzirwa kwakawanda pasina kukanganisa pamhando.

Vhidhiyo

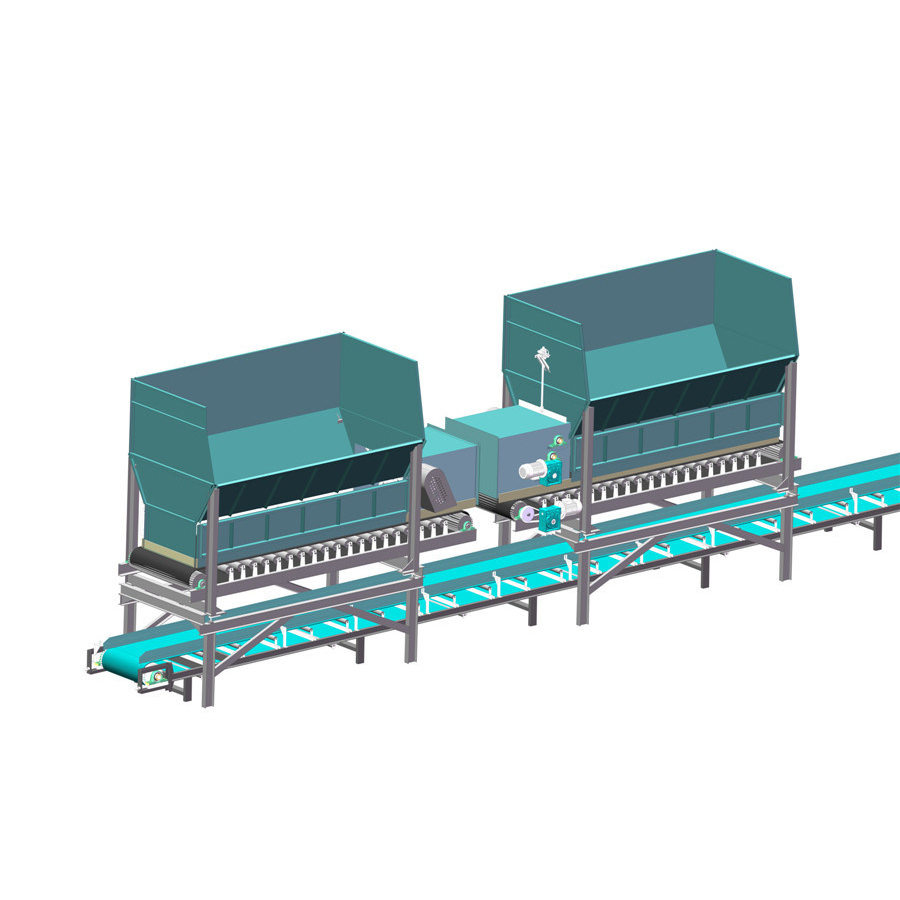

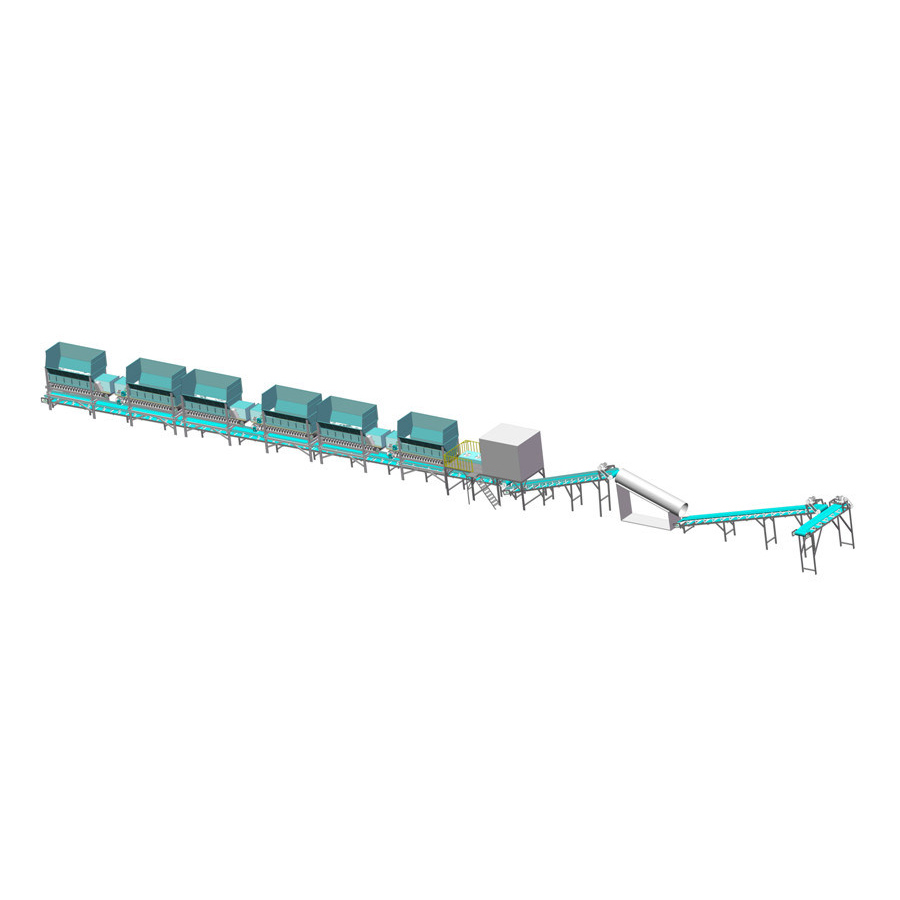

Intelligent batching system mabasa

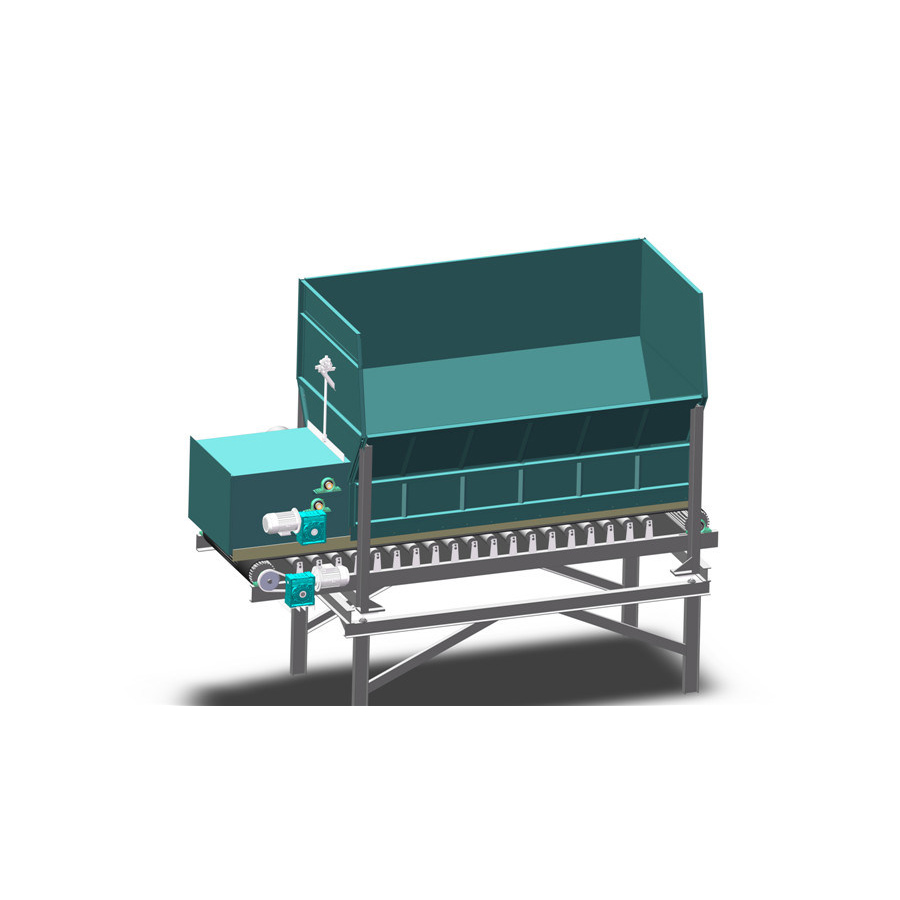

1. Iyo batching system yeWang Gong Weighing feeder inogona kusangana nezvinodiwa zvebhachi zvemhando dzakasiyana dzekugadzira zvigadzirwa, uye inogona kugadzirwa neakawanda mafeeders, ayo ari nyore kutanga, kushanda kwepamusoro, kuburitsa kwakanyanya, uye zvinhu zvakanaka.

2.Adopt touch screen display and button operation control.Iyo chaiyo-nguva huremu hwezvinhu uye mamiriro ekushanda ega ega anodyisa anoratidzwa pane yekubata skrini munguva chaiyo, uye chimiro chekushanda chemutakuri wega wega.Iyo inotarirwa huwandu hweiyo yakasarudzwa formula zvinhu, humidity (humidity inogona kugadziridzwa), chaiyo-nguva oversizing.

3.The feeding system control mode yakakamurwa kuva zvizere otomatiki mode uye manual mode

4. Chidzitiro chedhijitari chinoratidza uremu hwezvinhu mu feeder munguva chaiyo, uye nguva yekumira ye cycle mode mu automatic mode inoratidzwa kuburikidza ne countdown ye digital screen.Digital screen display “——-” apo chidyisa chisingadi kuita basa rekubika.

5.Conveyor control: Kana iyo conveyor otomatiki yekudyisa modhi, mushure mekunge mufudzi apedza kudya panguva imwe chete, mutakuri anofanira kunonoka kuendesa zvinhu zvemutakuri kukamuri yekusanganisa.

6.Iyo inodya yakashongedzerwa ne infrared grating, uye forklift loading inobata mutsara we grating apo iyo otomatiki mode inodyisa, uye mutsara wose unoramba uchishanda pakarepo kana mutakuri abuda mushure mekutakura.

7.Inopa shanduko yekuchinja pakutanga kwebheti uye kubuda kwekuchinja pamagumo ekugadzirisa

8.Kana iyo feeder yakaderera pane imwe uremu, mutsara wese unongomira kudyisa uye maalarm kuburikidza nemwenje wealarm.

9.Formula kuchengetedza 10, data yekudyisa inochengetwa kweinenge mwedzi mumwe, kupera kwemagetsi uye kukanganisa kurekodha uremu hwekudya.

System Advantage

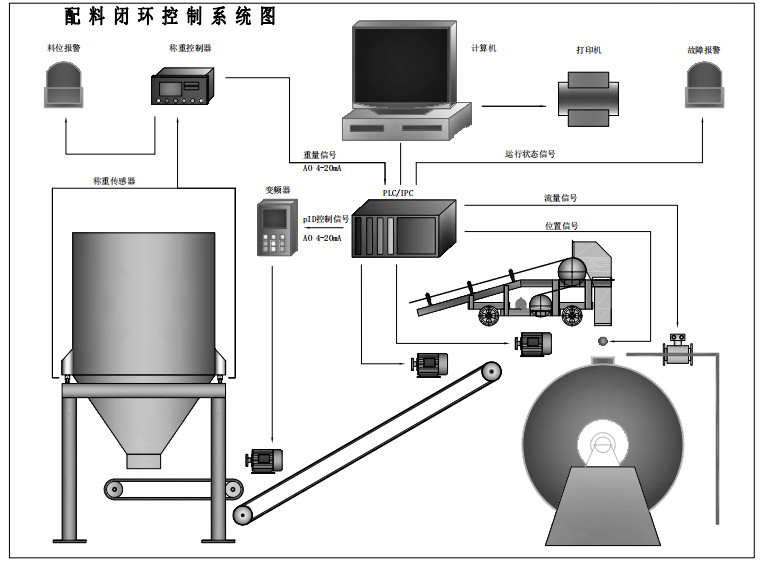

1: Iyo otomatiki batching system inotora programmable controller uye maindasitiri komputa seyakanyanya, iyo idiki muhukuru, yakakwirira mukurongeka uye yakanaka mukugadzikana.

2: Otomatiki batching system inogona kudzora akawanda mashekeri, akasiyana emhando dzakasiyana kana kudzora kubuda panguva imwe chete (zvichienderana nemaitiro)

3: Hungwaru kudzora kwebatching nguva, hapana kumirira pakati pezviyero zvezviyero, kuitira kuti batching kutenderera ipfupike, kuvandudza batching kumhanya uye kubuda.

4: Iyo otomatiki batching system inotora ichangoburwa system chikuva, iyo inomhanya nekukurumidza uye yakagadzikana, chaiyo-nguva inoshanduka yekugadzira skrini, inoratidza maitiro ekugadzira, intuitive mashandiro, akajeka uye otomatiki kudzoreredza basa.

5: Iyo otomatiki batching sisitimu ine simba reshumo basa, inogona kurekodha nekuchengetedza akasiyana marudzi edata uye kudhinda kwetafura muhuwandu hukuru, kuunganidza otomatiki uye kudhinda chinyorwa chemukati mushure mekugadzirwa kwega kwega kwapera, uye kupa zuva, nguva, nhamba yeshumo uye chaiyo. kushandiswa kwechinhu chimwe nechimwe;iyo yekudonhedza mushumo inotora iyo PC bhuku remubvunzo nzira, uye mushumo wekupedzisira wekugadzira unochengetwa mukati mekombuta, iyo inogona kuverengwa nekusingaperi kuti ive nechokwadi chekurongeka uye kutendeseka kwechinyorwa chekugadzira.

6: Kushanda kuri nyore, sisitimu ine bhuku, semi-otomatiki, yakazara otomatiki matatu ekugadzira modes.

7: Yakasimba data yekugadzirisa kugona, nekukurumidza uye yakagadzikana sampling mwero, batching maitiro anogona kuzadzisa zvizere zvinodikanwa zvekugadzira.

8: Iyo otomatiki batching system process inogona kusetwa zvinoenderana nemushandisi.

9: Kuvimbika kwakanaka, otomatiki batching system system ine maviri ekudzora zvirongwa (yekubata screen uye maindasitiri chirongwa chekombuta) Kana imwe yemarudzi ekunze iine chikanganiso, imwe yacho inokurumidza kucheka kushanda pasina kukanganisa kugadzirwa, uye otomatiki batching system inogona kubvisa kugadzirwa kunotiza chiitiko kana kutadza kwekugadzira kuchiitika.

10: Iyo otomatiki batching system inoratidza maitiro ekugadzira munguva chaiyo uye chinyorwa chinoratidza maitiro ekugadzira, ayo ari nyore kuti mushandisi ashande.

.

12: otomatiki batching system kufanana, imwe neimwe yakaunganidzwa nguva yekuburitsa ichishandisa frequency inoshandura kudzora kumhanya kwekuburitsa kuitira kuti imwe neimwe iunganidze panguva imwe chete kuburitsa, kuve nechokwadi chekufanana kweiyo batching.

. ita chiyeuchidzo basa, kuburikidza neiyo chaiyo-nguva online yekutarisa, tarisa iyo yakakosha ruzivo rwekugadzira chero nguva

Mashandiro anoita zvinhu zvebatching

Semuyenzaniso, otomatiki batching sisitimu inoumbwa 5 yemagetsi bhandi scale batching mitsara, nhamba 1#, 2#, 3#, 4#, 5#, iyo 1# ~ 4# iboka, 1# ndicho chinhu chikuru. chikero, uye zvitatu zvasara zvikero zvezvinhu zvebetsero.Kana pasina chikonzero chekuwedzera maexcipients, iyo 5# yemagetsi sikeri inoshanda yega kuendesa iyo huru zvinhu.Iyo sisitimu ine mabasa maviri: kugara kuyerera uye reshiyo kutonga.Kuti urambe uchiyerera, bhandi remagetsi rinogadzirisa zvinogadzirisa bhanhire rinokurumidza zvichienderana nehuwandu hwezvinhu zviri pabhanhire kuti zvizadzise seti inoyerera zvinodiwa.Maitiro ekuyerera kweiyo main scale (1#) system inoongororwa, uye mafambiro ekuita anoratidzwa mumufananidzo 1.

Mushure mekunge iyo otomatiki batching system yaiswa simba, iyo bhandi drive mota inotanga kutenderera, uye microprocessor inodzora kumhanya kwemota zvinoenderana nekushanda kwazvino.Zvinhu zviri muhopi zvinowira munzvimbo isina kuvhara uye zvinotakurwa nebhanhire kunzvimbo yekuyera, uko zvinhu zviri pabhanhire zvinoyerwa nemagetsi ebhanhire.Sero rinotakura rinoburitsa chiratidzo chevoltage zvichienderana nehukuru hwesimba, iro rinokwidziridzwa neanotapurirana kuti abudise metering level siginecha zvinoenderana nehuremu hwechinhu.Chiratidzo chinotumirwa kune chinongedzo chekombuta inotambira, sampled uye ichishandurwa kuita chiratidzo chetraffic, uye kukosha kwazvino kuyerera kunoratidzwa pakombuta inotambira.Panguva imwecheteyo, chiratidzo chekuyerera ichi chinotumirwa kuPLC interface, zvichienzaniswa nezvakasiyana zvinongedzo zvinotsanangurwa nekombuta inotambira, uyezve kugadzirisa kunoitwa, uye huwandu hwekutonga hunotumirwa kune frequency converter kushandura kukosha kwekubuda. iyo frequency converter, nekudaro ichichinja kumhanya kwemota yekutyaira.Rongedza iyo dosing kuitira kuti ienzane neyakaiswa kukosha kupedzisa otomatiki batching maitiro.

Parameter setting

| Dhizaini batching kugona | 0~120t/h |

| Kumira-oga kuyera kurongeka | 1/1000 |

| Batching system kunyatsoita | 2/1000 |

| Kufananidza kugadzirisa kurongeka | 1/1000 |

| Material particle size | ≤100mm(Maximum diagonal kureba) |

| Hunyoro hwezvinhu | ≤10% |

| System control mode | centralized, in-place control |

| Shandisa ambient tembiricha | -10℃~+45℃ |

| Shandisa hunyoro hunoenderana | ≤90%RH |

| System grid voltage | 380V±10%220V±10%;50Hz |

| Kukwanisa kwemagetsi | ≤200kw |

| System maitiro ekushanda | Continuous |

Zvido zvemusika

Ingredients idanho rakakosha mukugadzira mabhizinesi emaindasitiri, mhando, kunyatsoita uye kugadzikana kweiyo batching process inoita basa rakakosha mune yese indasitiri yekugadzira maindasitiri uye kunaka kwechigadzirwa, iyo yekudzokera kumashure ingredient system haingoite uye. zvisina kurongeka, mashandiro emaoko ezvigadzirwa uye kuunzwa kwezvinhu zvevanhu mu batching link, zvichikanganisa zvakanyanya kugadzikana uye nekuwedzera kuvandudzwa kwemhando yechigadzirwa, uye ine hukuru hwekushanda, kushaikwa kwekuchengetedzwa kwevashandi, kuchengetedza kwezvakatipoteredza hakusi kusvika kune mwero uye humwe hurema. , Zvigadzirwa zvakagadzirwa nemaoko zvinoita kuti zviome kuti kugadzirwa kwemaindasitiri kuonekwe mukugadzirwa kwakakura kwemaindasitiri.Naizvozvo, yakakwirira-chaiyo uye nehungwaru batching masisitimu ane kukosha kukuru kumabhizinesi emaindasitiri.

Basa rakakosha reChina riri kukurumidza kukurumidza "kugadzira chirimwa chekugadzira" uye iyo yakadzokera kumashure maindasitiri akangwara batching system indasitiri yakagadzira kupokana kukuru nemikana yemusika, zvichiita kuti misika yemumba ine hungwaru batching system musika wepasirese wemakwikwi, asiwo ichikwezva mari yepamba inopinda. yakawedzera mari muindasitiri yakangwara yezvigadzirwa zveindasitiri, uye nekushingairira kuvhura musika wepamba.

Intelligent batching control tekinoroji inoshandiswa zvakanyanya senge magetsi ekudzora tekinoroji, kuyerwa tekinoroji, tekinoroji yekunzwa, komputa software tekinoroji, mechanical tekinoroji, zvinhu uye makemikari tekinoroji uye mamwe akawanda-anoranga, akawanda-faceted nyanzvi tekinoroji, yakangwara batching control tekinoroji inonyanya kushandiswa mukati. maindasitiri ekugadzira mabhizinesi ezvigadzirwa, zvekubatsira kuyerwa kwezvinhu, kutakura, kuchengetedza uye kudya uye zvimwe zvinhu zvechinongedzo.

Application cases

Rinogona kuva basa redu kugutsa zvaunoda uye kubudirira kukushandira iwe.Mufaro wenyu ndiwo mubairo wedu wakanakisisa.Isu tanga takatarisira kuenda kune kuwedzera kwakabatana kweFactory Promotional Automatic Batching & Mixing & Conveying Systems yeExtruder Line, Isu tinovimba nemoyo wese pakuchinjana nekushandira pamwe newe.Titendere kuti tiende mberi takabatana maoko uye tiwane win-win situation.

Rinogona kuva basa redu kugutsa zvaunoda uye kubudirira kukushandira iwe.Mufaro wenyu ndiwo mubairo wedu wakanakisisa.Isu tanga takatarisira kuenda kune kuwedzera kwakabatana kweFactory Promotional Automatic Batching & Mixing & Conveying Systems yeExtruder Line, Isu tinovimba nemoyo wese pakuchinjana nekushandira pamwe newe.Titendere kuti tiende mberi takabatana maoko uye tiwane win-win situation.

Factory PromotionalChina Extruder uye Kusanganisa Machine, Zvivakwa zvakasimba ndiko kudiwa kweimwe sangano.Isu takatsigirwa nenzvimbo yakasimba yezvivakwa inoita kuti tikwanise kugadzira, kuchengeta, kutarisa kwemhando uye kutumira zvinhu zvedu pasi rese.Kuti tichengetedze kufamba kwakanaka, takaisa zvivakwa zvedu mumadhipatimendi akati wandei.Madhipatimendi ese aya anoshanda nemidziyo yazvino, michina yemazuva ano nemidziyo.Nekuda kweizvozvo, isu tinokwanisa kuzadzisa kugadzirwa kwakawanda pasina kukanganisa pamhando.

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat